What is good entrepreneurship for the world? Why are we (the common ones) fixated on it? What opportunities does it represent? Long ago, I raised these questions, and this is what I have found on my journey.

I have found both passionate people who want to fix the world but fail to run a business and business people with no passion for what they do. The better ones doing were balancing purpose and business, hence entering Circular Economy, the intersection where good business and not starving in the process meet. And it is still not easy to convey this. However, at the point I am rewriting this article (3 years after), things are changing. Mainly because the clock is ticking towards 2030, and the 1.5 Degrees, consumers are more aware and policy is facilitating transition towards it.

What makes a circular business?

Let’s take the case of VAER (back in the days called Wair), a hands-on company, bringing experts to work with novel circular business opportunities in fashion. It is a combination of innovation, practical product development through design thinking. Back in my early days, I learned a lot by working with them.

VAER’s creed stands for re-using resources that are out there, preventing the generation of further waste. By partnering with different organizations VAER is able to collect textiles that otherwise would have been trashed or incinerated. For instance, a collaboration with Europecar, the startup created new bags out of a discontinued uniform.

How can small businesses access circularity?

It all begins in the design stage; what and how things are going to be made define its value for society and the environment, and design for the lifecycle of the product or service. A great start is to slow down the flow of resources that run throughout production by designing products with a longer life or making them able to extend their life. Though some of the given examples may seem simple or common, it is about taking them across industries and replicating them that circularity is enhanced and expanded.

Designing longer-life products is about ensuring that they are used for a long period of time. This attribute also contributes to brand attachment and increasing trust. For example, depending on how old you are, you may remember your parents or grandparents’ fridges; these home appliances would go for decades without giving any kind of issue until they were obsolete decades after, and this was achieved by using materials that were durable and better quality.

Another strategy to slow down resources is designing products whose lifespan can be extended by re-use of the product, giving it maintenance, repairing, or upgrading it. For example, when a car has an issue, the mechanic can repair it by exchanging components or fixing pieces. Now one cannot say the same about phones, except if the screen gets broken.

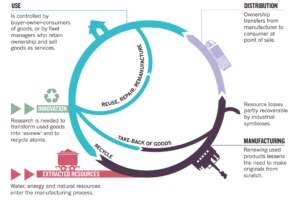

Once resources have been slowed down in the supply chain, a further step would be to actually close the loop. The illustration below gives a visualization of achieving this.

For this strategy, it is convenient to differentiate between a product that carries a service like phones, cars, and products that are meant for consumption like food, clothes, makeup, etc. A product designed for a service would require a technological cycle where designers aim to develop products that the materials can be continuously and safely recycled into new materials or products.

Products for consumption, on the other hand, would involve a biological cycle, meaning products are designed with safe and healthy materials that can become “food” for the ecosystem across their lifecycle. For instance, materials that can be degraded by biological activity such as composting or other biological processes. For example, the fashion industry is paying a lot of attention to new materials such as pinatex to create biodegradable fibers, but of course, there is a misconception that would be explored in future posts about biodegradable.

A third approach, design for disassembly, combines the already mentioned ones where it ensures that products and parts can be separated and reassembled easily. This strategy is vital for separating materials that will enter different cycles (biological and technological). A good analogy would be to think about Ikea products and their modularity. Each item can be put together and disassembled easily; the goal is to send each component to their respective cycle (technological or biological) to be reprocessed.

In a linear business, starting by slowing down the resources stream would be the best option so they can build momentum and develop circularity further. But there are challenges to working with circular models; here are some of the ones I have encountered:

- Working from non-standard or varying input of materials makes it complicated to have a standard production. That’s why Wair works on limited collections where each garment or item has a unique story to be told.

- Innovation can pose a challenge for partners’ mindset, especially manufacturers. Often these kinds of partners are comfortable with the way their business operates, and it is not relevant to be involved in new methods or partners that bring new ideas to the table.

- Scalability, it is often hard to source technologies that are largely accepted or embraced by the industry. For example, traditional dyeing, while is a very polluting process, less harmful alternatives such as bacteria dyeing are not yet embraced by a large number of manufacturers.

- Depending on the size of your company, you might feel limited action and can’t go far down/up the supply chain. Perhaps you will have to compromise some aspects and take action where you have direct control while being transparent. For instance, you want to reduce your CO2 footprint but you cannot control your supplier’s energy source, nor have the resources to engage in a project just be open about it and come back at it with the right time.

- Lack of social drive in the circular Economy movement. This is one of my biggest criticisms of the movement while it encompasses a focus on economical and environmental aspects. Now at WAIR, I’ve been looking to align partnerships to also contribute to society in this aspect.

Solutions are systemic. In the long-medium term, one cannot do things by its means; it is through collaborations with different stakeholders that a circular business model can be achieved.